One of the most important integral elements of a good speaker system is considered to be a subwoofer.

Of course, now there are many devices on the market for any configuration and by choosing the best subwoofer under $300 dollars you can satisfy the needs of a home audio system in low frequencies. But creating your equipment has its charm. When creating your subwoofer and for its high-quality and loud sound, you should take into account a large number of important nuances and the box is one of the most important.

Box requirements

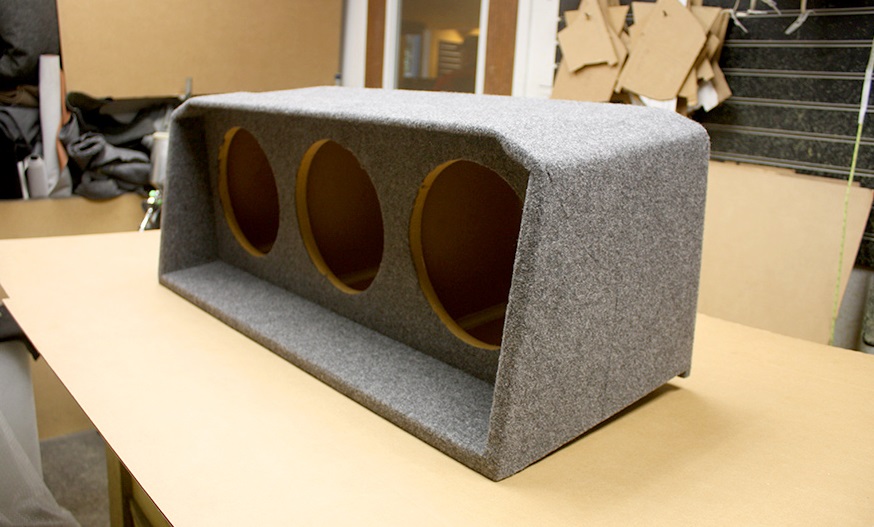

The box must be very reliable and strong enough so that, due to the vibrations of the low frequencies it generates, the sound does not get negative coloration.

Due to insufficient wall thickness, the rigidity of the box is underestimated. When sound is reproduced, the walls of the box begin to vibrate, that is, the entire box turns into a radiator, the sound waves that the box resonates, in turn, dampen the waves that the speaker emits from the front side.

The main requirement that a subwoofer box must meet is its rigidity and strength. The stiffer the walls, the less vibration generated by the subwoofer during operation.

Types of materials for a subwoofer

Plywood

One of the most popular materials for making acoustic equipment. But there are also a couple of downsides: this is the most expensive material. It is difficult to find plywood more than 18 mm thick. With a large wall area, it starts to “ring” (additional stiffening ribs or spacers are needed).

MDF

It is a kind of gap between plywood and chipboard. Its main advantage is that the price is lower than that of plywood (about the same as for chipboard), good rigidity (but does not reach the level of plywood). Easy to saw. Moisture resistance is higher than that of the chipboard. It is problematic, but it is possible to find a thickness of more than 18 mm.

Chipboard

Cheap, common material. There is in every furniture company, in the same companies you can order and saw cut. This box will cost you 2-3 times cheaper than plywood. Disadvantages:very low material stiffness; not moisture resistant. It absorbs moisture well and crumbles.